About us

A 100% women owned and operated company

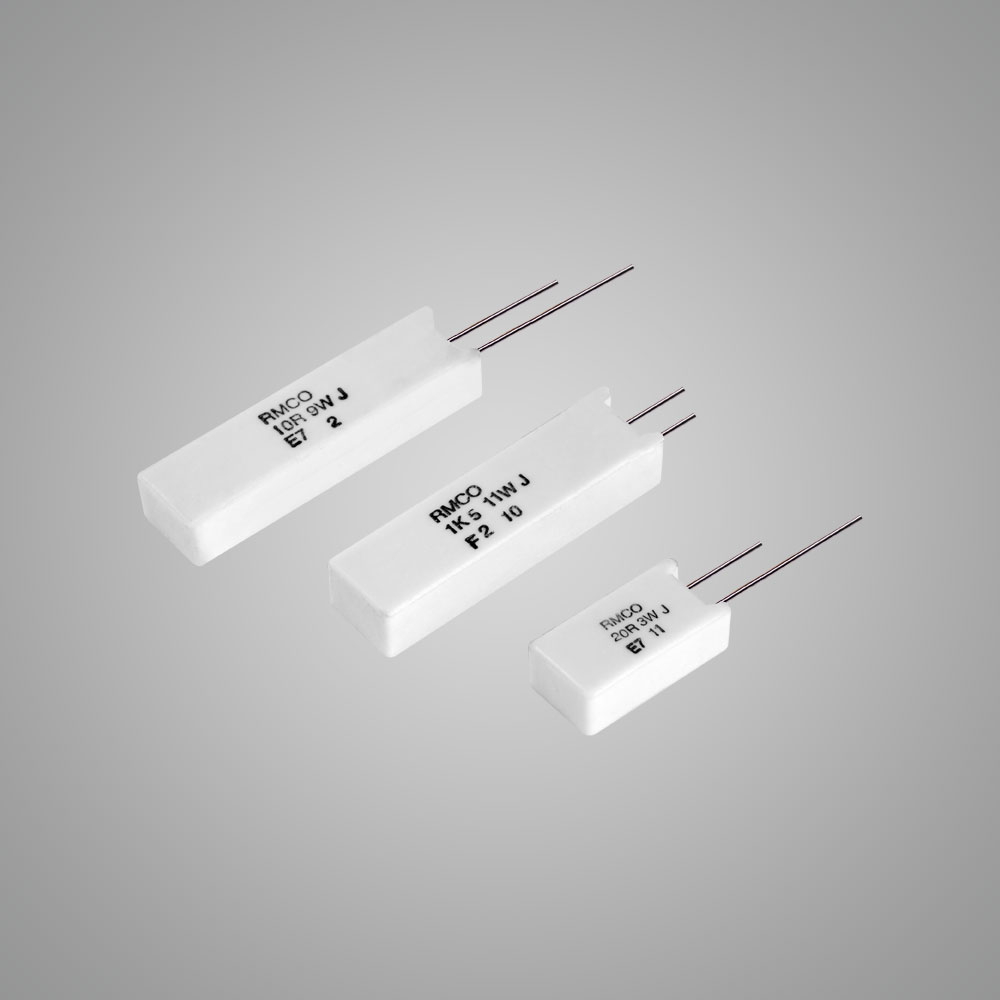

Manufacturer of customized high precision wire wound resistors

When you think of high precision wire wound resistors, think RMC. Don’t take our word for it. Ask blue chip companies like GE, Alstom, Schneider Electric and Bosch why RMC is their preferred vendor. The answer would not be the cliché ‘quality‘, ‘timely delivery‘ etc. That is a given. It would be RMC’s one-on-one interaction, with clients, to understand their requirements. And custom make the resistors.

Whether it is the high volume or low volume, special packaging or presentation including customized colours. And value adds like private labelling. While RMC’s esteemed certifications for quality are no doubt a matter of pride, it is RMC’s commitment to employee safety, hygiene and environmental concerns that give us the edge.

RMC’s compliance to global standards, as prescribed by OEMs, is not only because it is subject to social accountability and audit but because RMC truly believes that these are priorities in a manufacturing plant.

Now you know why manufacturers of Power supplies, Locomotives, Medical Electronics, EMS companies, Automotive and Energy Meters think of RMC when they think of RESISTORS.